| |

|

|

from the issue of August 17, 2006

|

| |

|

|

| |

Shop expertise aids ANDRILL

BY TROY FEDDERSON, UNIVERSITY COMMUNICATIONS

Michael Jensen has no desire to follow his newest research-related creation into the field.

| |

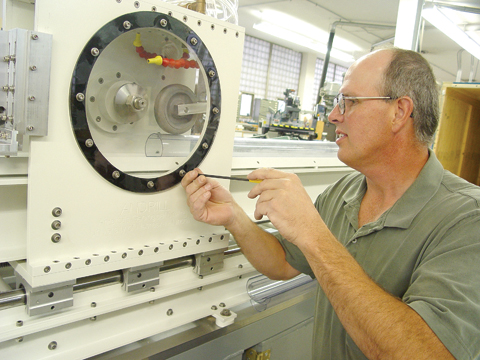

| | | SPLIT DESIGNER - Michael Jensen, manager of the Chemistry/Physics and Astronomy Instrument Shop, tightens a protective shield onto the ANDRILL core splitter he designed for the five-nation, UNL-led geological drilling program based in Antarctica. Jensen, a UNL graduate, spent over 500 hours on the design and build of the core splitter. Photo by Troy Fedderson/University Communications.

|

For the second time as manager of the Chemistry/Physics and Astronomy Instrument Shop, Jensen has designed and built a device that will play an important role in ANDRILL, the UNL-led geological drilling project based in Antarctica.

Jensen's first ANDRILL build was a shield that successfully protected an ocean current monitor from damage. In response, Richard Levy, co-leader of ANDRILL, contacted Jensen to see if he was interested in a new project.

During their discussion, Levy explained that ANDRILL needed what was basically a super-charged saw that could split rock cores collected from beneath frozen seas. ANDRILL researchers use the cores to study global climate change - half of the core is used for study today, the other half is saved for future research efforts.

"Richard contacted me in December and wanted to know if we could make them a core splitter," Jensen said. "I had an idea of what it was and thought it would be a great challenge."

Despite an interest in machines, Jensen once would have let such a challenge pass him by. An unmotivated high school student, Jensen graduated and began working for the Nebraska Department of Roads. However, standing on a lonesome stretch of Highway 30 directing cattle trucks in the middle of winter got him thinking.

"I told myself, 'Mike, you need to find a job that is air conditioned in the summer and heated in the winter,'" Jensen said. "I had always fooled around with cars and motorcycles, so I decided to check out what it took to become a tool and dye maker."

After two years of additional education, Jensen took a job with Square D in Lincoln. He then opted to see if his know-how would cut it at UNL.

"I decided to take two math, two chemistry and two physics courses and see if I could pass them," Jensen said. "I did and they made me pick a major so I went with mechanical engineering. I told myself I'd go until I flunked out."

That day never came.

While he pursued his bachelor's degree, Jensen started working at the UNL Chemistry Shop in 1984. He earned the degree in 1990 and continued to work in the shop, becoming an instrument maker when the Chemistry and Physics and Astronomy shops merged in 1998. When Jack Loss retired in 2002, Jensen became the shop's interim manager. In 2003, he was promoted to manager.

The shop has continued to grow under Jensen. He however passes credit to the shop staff, which includes student shop manager Les Marquart, and instrument makers Keith Placek, Pat Pribil and Robert Rhynalds.

During the 2005-2006 fiscal year, Jensen said the shop completed more than 300 projects for research efforts in Chemistry, Physics and Astronomy. One of those jobs - the core splitter - absorbed 500 hours of design, build and testing time.

After the call from Levy, Jensen was flown to examine core splitters at Florida State University and Texas A&M. As he learned about the splitter specs and the environment it would be used in, Jensen realized the job was an engineer's dream.

"I had to design this so it was as easy as possible to operate and repair," Jensen said. "It needs to be durable because they work 12-hour shifts in specialized shipping containers. They are heated, but with the confined space and no windows it would make for some long days."

To assure durability, Jensen over engineered the ANDRILL core splitter, incorporating redundancies that allow salvaging between parts to continue operation. Tools and parts needed to keep the machine running are housed in a storage area that doubles as the splitter's base.

To keep the one-of-a-kind splitter under budget, Jensen incorporated mass-produced parts. For example, 12-foot guide screws and the power feed on the ANDRILL core splitter are the same ones used in milling machines in the Chemistry/Physics and Astronomy Instrument Shop.

Like any engineer building a machine for the first time, Jensen was worried the splitter would fail. So, he came in to work early one day and tested it on a handful of superhard, volcanic samples provided by the ANDRILL office.

"I used the hand feed the first time and was surprised at how easily it cut," Jensen said with a smile. "It was amazing because you could feel it cutting through hard spots then soft spots. It didn't take long to get a feeling for how to operate it."

| | SHOP WORK - Keith Placek, an instrument maker in the Chemistry/Physics and Astronomy Instrument Shop, mills a nylon piece of a sputtering gun for a UNL researcher. The shop, located in Ferguson Hall, includes five employees. hoto by Troy Fedderson/University Communications.

| |

After a few minor alterations - including a beefed up debris shield, a specialized washer attachment and an apparatus to cut plastic tubes that hold soft cores - Jensen had the core splitter ready for travel.

He conducted a final test with Levy Aug. 9. And the core splitter was scheduled to ship out Aug. 11 for a journey to the west coast, New Zealand and finally McMurdo Sound in Antarctica.

Jensen said he takes pride in knowing the core splitter he designed is going to play a role in helping researchers better understand previous changes in the global climate. But, his one hope is to never have to answer a repair call to McMurdo Sound.

"That is the one phone call I don't want to ever receive," Jensen said. "I really enjoyed working on this core splitter, but I hope to never hear about it again. If that's the case, then I know I've done the job right."

For more information on the Chemistry/Physics and Astronomy Instrument Shop, go online to www.chem.unl.edu/ishop.

GO TO: ISSUE OF AUGUST 17

NEWS HEADLINES FOR AUGUST 17

Research funding tops $100 million milestone

Shop expertise aids ANDRILL

Summer Construction Updates

Traffic rolls across half of Big X

UNL.edu update unveiled

Campus residence halls start year over capacity

Expect delays as students return to UNL

From the Archives

Scientists link wind shift, Sandhills mega-drought

Students create tiles for Selleck dining hall

U.N. ambassador opens Thompson series

United Kingdom terror arrests delay UNL students' return

UNL bus routes trimmed, garage-only route added

732540S35984X

|

|

|

|

|

|

|

|